We are committed to providing one-stop service for steel pipe products to customers around the world.

We are committed to providing one-stop service for steel pipe products to customers around the world.

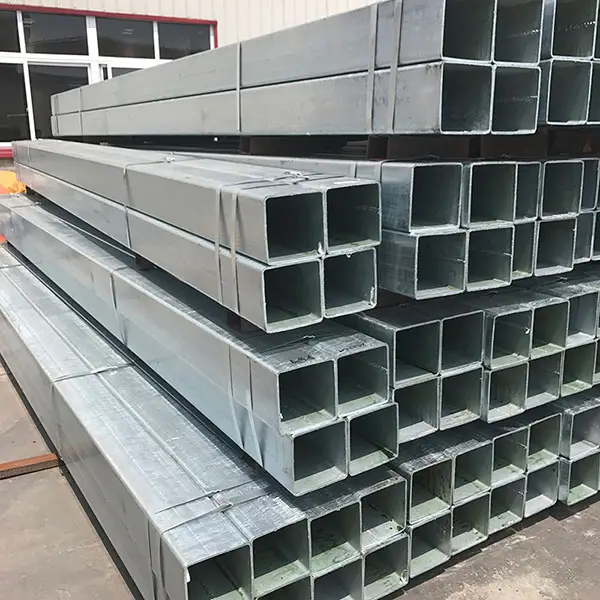

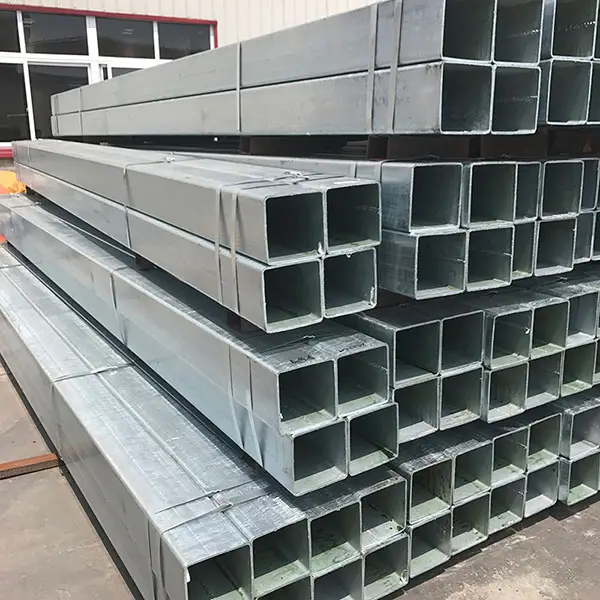

Square tube is formed from coil and then ran through a series of dies. It’s welded from the inside to form its shape. Square tubes are generally used for maintenance and structural purposes.

Some examples of square tubing applications would be building construction, railings, and sign posts. They are measured by their outside dimensions and their wall thickness.

Square Tube is available in the following metal types:

Alloy Steel

Mild Stee

Carbon Steel

Stainless Steel

Square tube has similar uses to RHS and is used for both industrial and construction applications. Square section RHS is available in the same thicknesses as RHS and dimensions range from 20 mm x 20 mm to 400 mm x 400 mm.

|

Size by Inch (diameter) |

Thickness |

Sizes by MM (diameter) |

Thickness |

|

inch |

inch |

mm |

mm |

|

1/2" x 1/2" |

0.065" |

16mm×16mm |

0.4mm~1.5mm |

|

3/4" x 3/4" |

0.049" |

18mm×18mm |

0.4mm~1.5mm |

|

0.065" |

20mm×20mm |

0.4mm~3mm |

|

|

0.083" |

22mm×22mm |

0.4mm~3mm |

|

|

0.120" |

25mm×25mm |

0.6mm~3mm |

|

|

1" x 1" |

0.049" |

30mm×30mm |

0.6mm~4mm |

|

0.058" |

32mm×32mm |

0.6mm~4mm |

|

|

0.065" |

34mm×34mm |

1mm~2mm |

|

|

0.072" |

35mm×35mm |

1mm~4mm |

|

|

0.083" |

38mm×38mm |

1mm~4mm |

|

|

0.095" |

40mm×40mm |

1mm~4.5mm |

|

|

0.109" |

44mm×44mm |

1mm~4.5mm |

|

|

0.120" |

45mm×45mm |

1mm~5mm |

|

|

1 1/8" x 1 1/8" |

0.035" |

50mm×50mm |

1mm~5mm |

|

0.049" |

52mm×52mm |

1mm~5mm |

|

|

0.065" |

60mm×60mm |

1mm~5mm |

|

|

0.109" |

70mm×70mm |

2mm~6mm |

|

|

0.120" |

75mm×75mm |

2mm~6mm |

|

|

1 1/4" x 1 1/4" |

0.049" |

76mm×76mm |

2mm~6mm |

|

0.065" |

80mm×80mm |

2mm~8mm |

|

|

0.072" |

85mm×85mm |

2mm~8mm |

|

|

0.083" |

90mm×90mm |

2mm~8mm |

|

|

0.109" |

95mm×95mm |

2mm~8mm |

|

|

0.120" |

100mm×100mm |

2mm~8mm |

|

|

0.135" |

120mm×120mm |

4mm~8mm |

|

|

0.156" |

125mm×125mm |

4mm~8mm |

|

|

0.188" |

130mm×130mm |

4mm~8mm |

|

|

1 1/2" x 1 1/2" |

0.049" |

140mm×140mm |

6mm~10mm |

|

0.065" |

150mm×150mm |

6mm~10mm |

|

|

0.072" |

160mm×160mm |

6mm~10mm |

|

|

0.083" |

180mm×180mm |

6mm~12mm |

|

|

0.109" |

200mm×200mm |

6mm~30mm |

|

|

0.120" |

220mm×220mm |

6mm~30mm |

|

|

0.140" |

250mm×250mm |

6mm~30mm |

|

|

0.188" |

270mm×270mm |

6mm~30mm |

|

|

0.250" |

280mm×280mm |

6mm~30mm |

|

|

1 3/4" x 1 3/4" |

0.065" |

300mm×300mm |

8mm~30mm |

|

0.083" |

320mm×320mm |

8mm~30mm |

|

|

0.095" |

350mm×350mm |

8mm~30mm |

|

|

0.109" |

380mm×380mm |

8mm~30mm |

|

|

0.120" |

400mm×400mm |

8mm~30mm |

|

|

0.188" |

420mm×420mm |

10mm~30mm |

|

|

2" x 2" |

0.049" |

450mm×450mm |

10mm~30mm |

|

0.065" |

480mm×480mm |

10mm~30mm |

|

|

0.083" |

500mm×500mm |

10mm~30mm |

|

|

0.109" |

550mm×550mm |

10mm~40mm |

|

|

0.120" |

600mm×600mm |

10mm~40mm |

|

|

0.145" |

700mm×700mm |

10mm~40mm |

|

|

0.165" |

800mm×800mm |

10mm~50mm |

|

|

0.188" |

900mm×900mm |

10mm~50mm |

|

|

0.250" |

1000mm×1000mm |

10mm~50mm |

|

|

0.312" |

|

|

|

|

2 1/4" x 2 1/4" |

0.188" |

|

|

|

0.250" |

|

|

|

|

2 1/2" x 2 1/2" |

0.083" |

|

|

|

0.109" |

|

|

|

|

0.120" |

|

|

|

|

0.188" |

|

|

|

|

0.250" |

|

|

|

|

0.312" |

|

|

Dimensional Tolerances

|

Dimensional Tolerances |

|||

|

Outside Diameter: |

Twist: |

Maximum twist per 3 feet of length |

|

|

Largest outside dimension |

Outside tolerance including convexity and concavity |

Longest outside dimension |

|

|

up to 2 1/2" |

±.020" |

2" to 2 1/2"inclusive |

.062" |

|

over 21/2" to 31/2" inclusive |

±.025" |

over 21/2" to 4" inclusive |

.075" |

|

over 31/2" to 51/2" inclusive |

±.030" |

over 4" to 6" inclusive |

.087" |

|

over 51/2" |

±1% |

over 6" to 8" inclusive |

100" |

|

Tolerances include allowance for convexity or concavity. For |

over 8" |

112" |

|

|

Straightness: |

|||

|

.125" x (total length) ÷ 5 |

|||

|

Wall Thickness: |

Squareness of Sides: |

||

|

Maximum allowable variation |

±10% |

Adjacent sides may deviate from 90° by a tolerance of plus or minus 2 degrees maximum. |

|

|

(wall thickness is to be measured at the center of the flat, exclusive |

|||

|

Worner Radii: |

Flash: |

||

|

The radius of any outside corner shal not exceed three times |

Structural tubing usually is supplied flash-in. The height of the |

||

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

|

|

Chemistry-Ladle Analysis |

|||

|

Carbon |

Manganese |

Phosporous |

Sulfur |

|

|

A501 (A36) |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500A |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500B |

0.26% max |

- |

0.04% max |

0.05% max |

|

A500C |

0.23% max |

1.35% max |

0.04% max |

0.05% max |

|

Copper, when copper steel is specified, 0.20% minimum. |

||||

|

Mechanical Properties |

||||

|

Grade Designation |

Grade |

Tensile Strength |

Yield Strength Minimum |

Elongation In 2 Inches Minimum |

|

Condition |

Minimum |

|||

|

A501 (A36) |

Hot Formed |

58,000 psi |

36,000 psi |

23% |

|

A500A |

Cold Formed |

45,000 psi |

39,000 psi |

25% |

|

A500B |

Cold Formed |

58,000 psi |

46,000 psi |

23% |

|

A500C |

Cold Formed |

62,000 psi |

50,000 psi |

21% |